In many industries, from packaging to electronics, the need for precise and efficient tape cutting is a daily requirement. A tape cutting machine offers a practical solution for handling different types of adhesive materials, making it easier for businesses to improve workflow while maintaining consistency in production.

A tape cutting machine is designed to automatically cut tape into set lengths, eliminating the need for manual measuring and cutting. This automation reduces the chances of errors caused by human handling, which can result in uneven tape edges or wasted material. By setting the desired cutting length and speed, operators can ensure that each piece of tape meets specific requirements, whether for product assembly, packaging, or industrial use.

One of the main benefits of using a tape cutting machine is the ability to work with a variety of tape types. It can handle single-sided adhesive tape, double-sided tape, fabric tape, protective film, and other specialized materials. Adjustable cutting lengths and programmable batch functions give the operator full control over the process, making it easy to switch between different applications without the need for multiple tools.

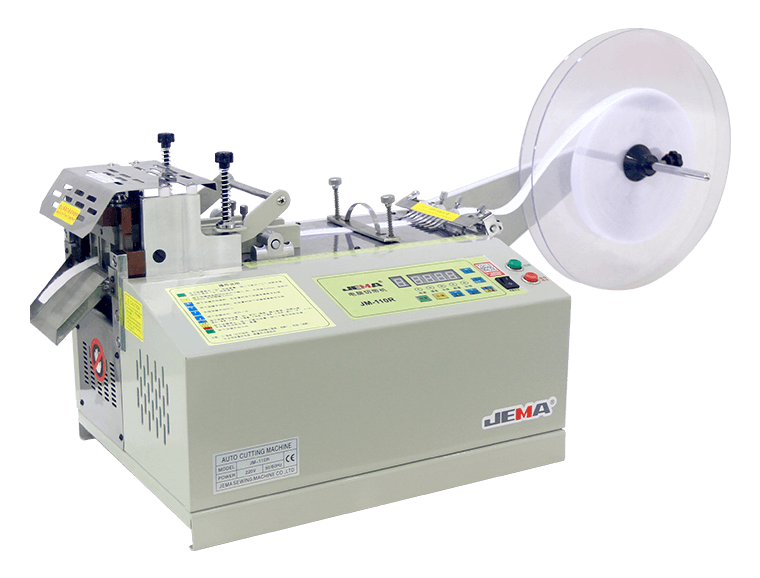

Another useful feature often found in modern tape cutting machines is their compact and efficient design. These machines can fit comfortably on a workbench or production line, taking up minimal space while delivering reliable performance. Their size makes them suitable for both large factories and small workshops looking to improve output without significant equipment investment.

In terms of operation, tape cutting machines are straightforward to use. Most systems offer digital controls or simple button functions, allowing for quick adjustments and minimal training time for new users. Safety features such as automatic stop sensors and material jam detection are also commonly included, ensuring smooth operation and protecting both the machine and the operator.

For businesses managing repetitive cutting tasks, a tape cutting machine helps improve efficiency by saving time and reducing manual labor. It allows for continuous cutting or on-demand dispensing, depending on the production needs. This flexibility makes it a reliable tool for industries such as garment manufacturing, electronics assembly, printing, and product packaging.

Additionally, the ability to control cutting precision ensures better use of materials, reducing waste and supporting cost management goals. By consistently cutting tape to exact lengths, companies can maintain product quality standards and enhance their production processes.

In summary, a tape cutting machine is a valuable tool for a range of applications. Its ability to handle different materials, combined with automated functions and easy operation, makes it a practical choice for businesses aiming to improve productivity and maintain consistent quality in their processes.