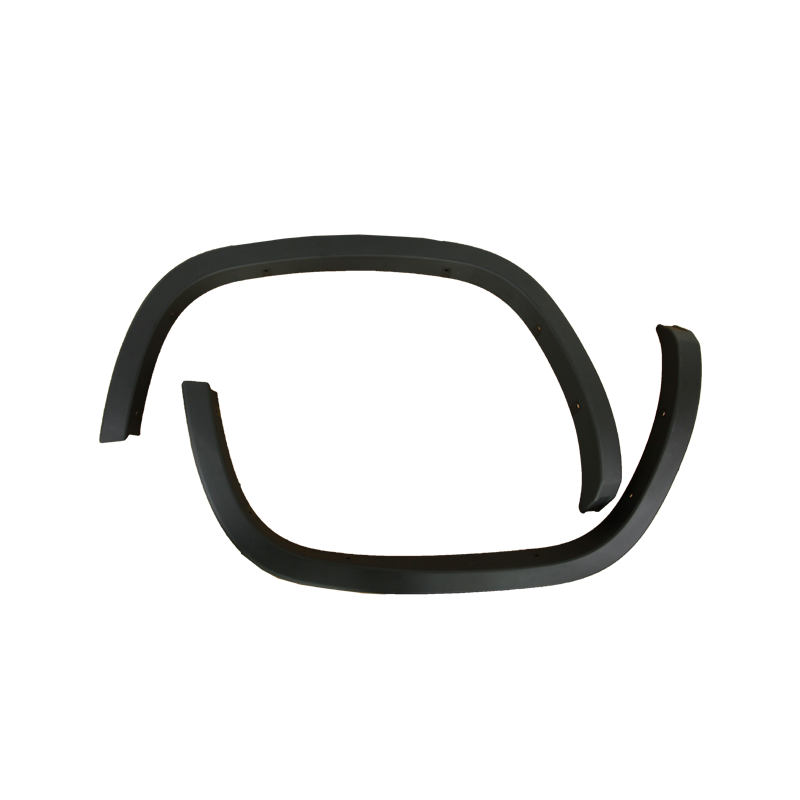

Redefining durability in modern vehicles, our engineered common automotive plastic delivers exceptional structural integrity where it matters most. Specially formulated for demanding automotive applications, this common automotive plastic combines superior impact resistance with unmatched load-bearing capacity – making it the trusted choice for critical safety components like bumpers, dashboards, door panels, and pillar trims. Unlike conventional plastics that crack under stress or degrade over time, this advanced common automotive plastic maintains its toughness through extreme temperature cycles, UV exposure, and mechanical shocks.

The secret lies in its polymer matrix reinforced with impact modifiers and stabilizers. When subjected to collision forces, this common automotive plastic absorbs and disperses energy rather than shattering, significantly enhancing passenger safety in crumple zones. Its exceptional resistance to deformation prevents warping even when supporting heavy integrated electronics in dashboards or enduring constant entry/exit stress on door panels. For automakers prioritizing both safety and longevity, this common automotive plastic provides a fatigue-resistant solution that outlasts the vehicle’s lifespan.

Beyond crash performance, this common automotive plastic excels in daily resilience:

✅ 15,000+ hour UV resistance (prevents fading/brittleness)

✅ -40°C to 120°C operational stability (no cold-weather embrittlement)

✅ Chemical resistance (immune to oils, cleaners, and road salts)

✅ Creep reduction technology (maintains dimensional accuracy)

Manufacturers choose this common automotive plastic for its unique balance of performance and processability. It flows effortlessly into complex molds for integrated clip designs and textured surfaces, reducing assembly parts by up to 30% versus metals. The material’s inherent vibration-damping properties also contribute to cabin quietness – an often-overlooked benefit of this versatile common automotive plastic.

From withstanding shopping cart dings in parking lots to surviving off-road debris impacts, components crafted from this common automotive plastic offer measurable advantages:

-

40% lighter than equivalent steel components

-

50% faster production cycles vs. thermoset composites

-

Zero corrosion throughout vehicle lifecycle

Whether reinforcing bumper beams for 5MPH crash compliance or creating scratch-resistant interior trim, this common automotive plastic sets new standards for affordable durability. It’s not just a material – it’s the invisible guardian of vehicle integrity. Trust the engineered polymer that performs when safety hangs in the balance: the extraordinary common automotive plastic built to protect.