Since plastic food container moulds are subjected to repeated cycles during the injection molding process, it's essential that they can endure wear and tear over time without losing their functionality. Durability is particularly important for moulds used in high-volume manufacturing, as any failure could lead to significant production downtime and increased costs.

Durability testing for plastic food container moulds typically involves several methods. One common test is cyclic stress testing, where the mould is subjected to repeated heating, cooling, and injection pressures to simulate the stresses it will face in the manufacturing process. This helps assess how well the mould can handle extreme conditions and how long it will last before showing signs of degradation. Additionally, impact resistance testing ensures that the moulds can withstand accidental damage during production or handling.

By ensuring that the plastic food container moulds pass these durability tests, manufacturers can guarantee that the moulds will maintain their performance and integrity throughout their lifespan, minimizing the risk of unexpected failures.

While testing the finished plastic food container moulds is essential, maintaining quality control throughout the production process is just as important. The first step is to ensure that the materials used to create the moulds meet high-quality standards. This includes verifying the type of plastic or metal used and ensuring that it is of the highest grade for durability and safety.

Regular inspections during the production of plastic food container moulds are also essential. These inspections often involve checking the quality of the mould cavities, monitoring the flow of the material during injection molding, and verifying that the moulds are cooling correctly. Using automated monitoring systems helps maintain consistency and ensures that each batch of plastic food container moulds meets the required specifications.

In addition, it is vital to conduct pressure tests to assess the uniformity of the material flow. This ensures that the plastic food container moulds are produced with a consistent density and that any weak points are identified before the moulds reach the final production stage.

https://www.food-container-mold.com/product/disposable-plastic-square-food-container-moulds/square-product-mold.html

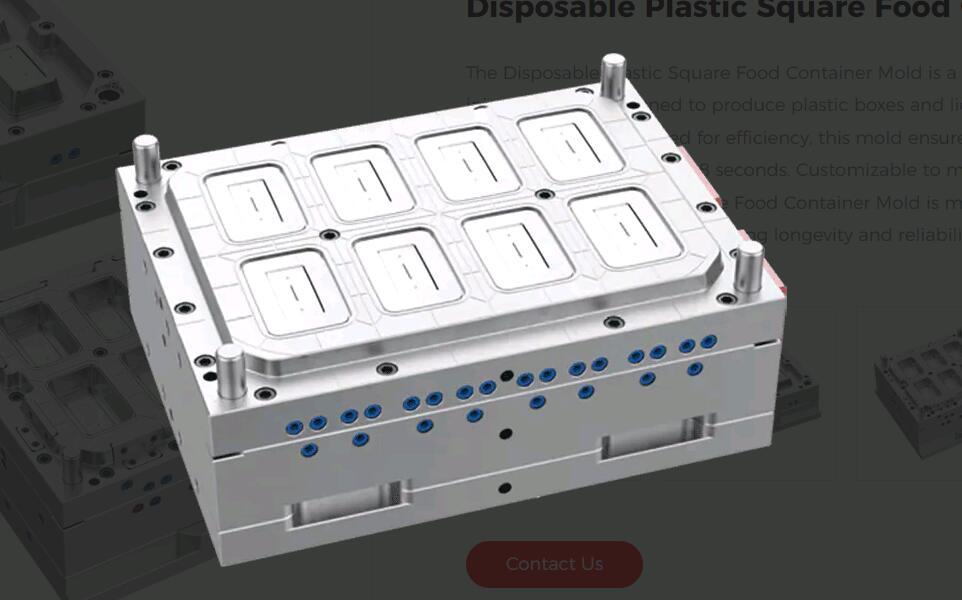

The Disposable Plastic Square Food Container Mold is a high-precision plastic injection mold designed to produce plastic boxes and lids with excellent sealing performance. Engineered for efficiency, this mold ensures a swift molding cycle of just 6 seconds or within 6-8 seconds. Customizable to meet specific requirements, the Disposable Plastic Square Food Container Mold is made from durable PP (polypropylene) material, ensuring longevity and reliability.