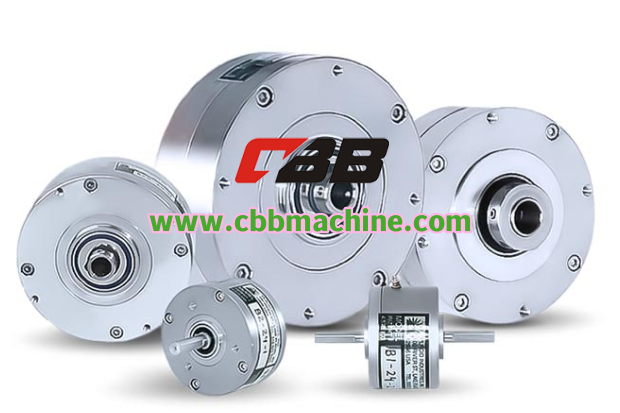

In the realm of high-performance industrial manufacturing, CBBMachine has cemented its reputation as a trusted Magnetic Powder Clutch factory , delivering systems that epitomize precision, durability, and adaptability. Renowned for its innovative approach, the company caters to industries such as automotive engineering, renewable energy, and advanced robotics, where exacting standards for torque control and operational efficiency are paramount. By harmonizing state-of-the-art technology with client-specific solutions, CBBMachine continues to redefine the boundaries of modern manufacturing.

Advanced Techniques in Frictionless System Production

CBBMachine’s manufacturing facility employs a blend of robotic automation and human expertise to craft magnetic powder clutches that excel in demanding environments. The production process incorporates precision CNC machining, real-time laser alignment, and AI-powered quality checks to ensure each component meets rigorous tolerances. From automotive assembly lines requiring rapid torque adjustment to wind turbine systems demanding flawless power transmission, these clutches are engineered to perform under extreme conditions, including high humidity, corrosive atmospheres, and rapid thermal shifts.

Quality Assurance and Tailored Engineering

Every clutch undergoes a multi-stage validation process, including stress tests for cyclic fatigue, electromagnetic compatibility trials, and load endurance simulations. Clients collaborate with CBBMachine’s engineers to customize parameters such as response speed, torque capacity, and environmental hardening—like food-grade coatings for packaging machinery or dustproof seals for construction equipment. The factory’s modular design framework allows seamless integration into both legacy infrastructure and Industry 4.0-ready systems, enabling features such as IoT connectivity for predictive maintenance and real-time performance analytics.

Sustainability at the Core of Manufacturing

CBBMachine prioritizes eco-friendly practices throughout its operations. The facility utilizes renewable energy sources, including solar and geothermal power, to reduce its carbon footprint. Closed-loop cooling systems and 98% material recycling rates minimize waste, while low-emission coatings and biodegradable lubricants align with global sustainability mandates. In electric vehicle battery production, these clutches enhance energy efficiency by optimizing power distribution, contributing to greener manufacturing cycles.

Cross-Industry Applications Driving Technological Progress

The factory’s R&D initiatives have unlocked innovative applications across diverse sectors. In precision agriculture, magnetic powder clutches enable variable-speed seeding drones to adapt to soil conditions, improving crop yields. The entertainment industry relies on silent, vibration-free units for automated stage rigging, while pharmaceutical lines use hygienic designs to maintain sterile conditions during pill blistering. Recent advancements include ultra-compact clutches for micro-factory robots and high-torque variants for cargo drone propulsion systems, showcasing CBBMachine’s versatility in addressing emerging challenges.

Collaborative Partnerships for Future-Ready Solutions

CBBMachine fosters long-term relationships with clients through co-development projects and technical support. Whether designing explosion-proof units for oil refineries or creating IoT-enabled systems for smart warehouses, the factory’s engineering team delivers solutions tailored to unique operational needs. Digital twin technology allows clients to simulate clutch performance in virtual environments, reducing prototyping costs and accelerating time-to-market for new machinery.

Transform Your Industrial Capabilities

For industries seeking cutting-edge, reliable, and sustainable torque control solutions, CBBMachine stands as a partner in innovation. Welcome to visit our website to explore how our expertise in precision manufacturing can elevate your operations.

Explore further at: www.cbbmachine.com