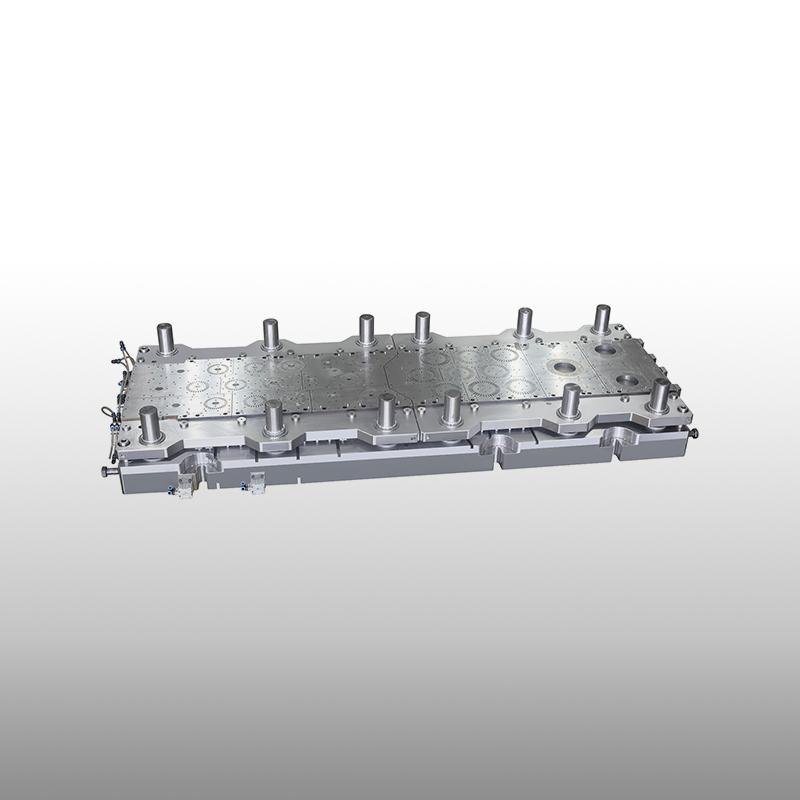

In the realm of manufacturing, precision and efficiency are paramount, and Custom Metal Molds stand as a testament to these values. These meticulously designed molds are crafted to fit the specific needs of each unique production process, ensuring that every product meets the highest quality standards. The advantages of Custom Metal Molds are multifaceted, offering unparalleled precision, durability, and cost-effectiveness. One of the primary benefits of Custom Metal Molds is their ability to produce parts with exacting specifications. This precision is crucial in industries where tolerances are tight and product integrity is essential. By utilizing Custom Metal Molds, manufacturers can achieve a level of detail that is simply not possible with standard, off-the-shelf molds. Durability is another key advantage of Custom Metal Molds. These molds are engineered to withstand the rigors of high-volume production, reducing the need for frequent replacements and minimizing downtime. This longevity not only saves on material costs but also contributes to a more sustainable production process. Furthermore, Custom Metal Molds contribute to cost savings in the long run. While the initial investment may be higher than that of generic molds, the return on investment is significant due to reduced maintenance and the ability to produce a higher volume of parts with greater consistency. This leads to increased efficiency and profitability for businesses. In conclusion, Custom Metal Molds offer a competitive edge in the manufacturing sector. Their precision, durability, and cost-effectiveness make them an invaluable asset for any company looking to produce high-quality products with consistency and reliability. By embracing the customization of metal molds, manufacturers can elevate their production capabilities to new heights.